Process

We have advanced technology to bring perfection in work, and easy availability of raw material and other resources for fair business.

Process

Flow

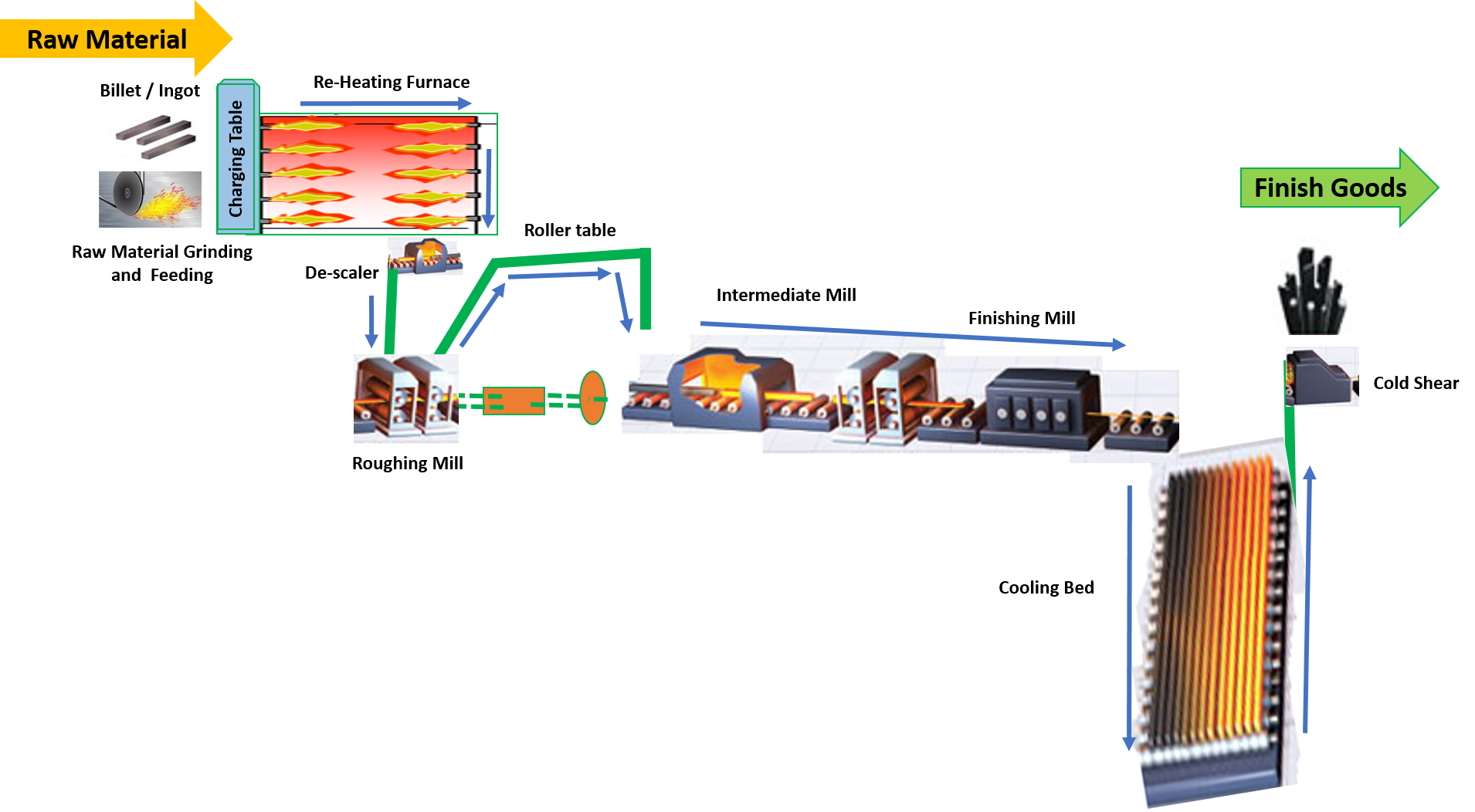

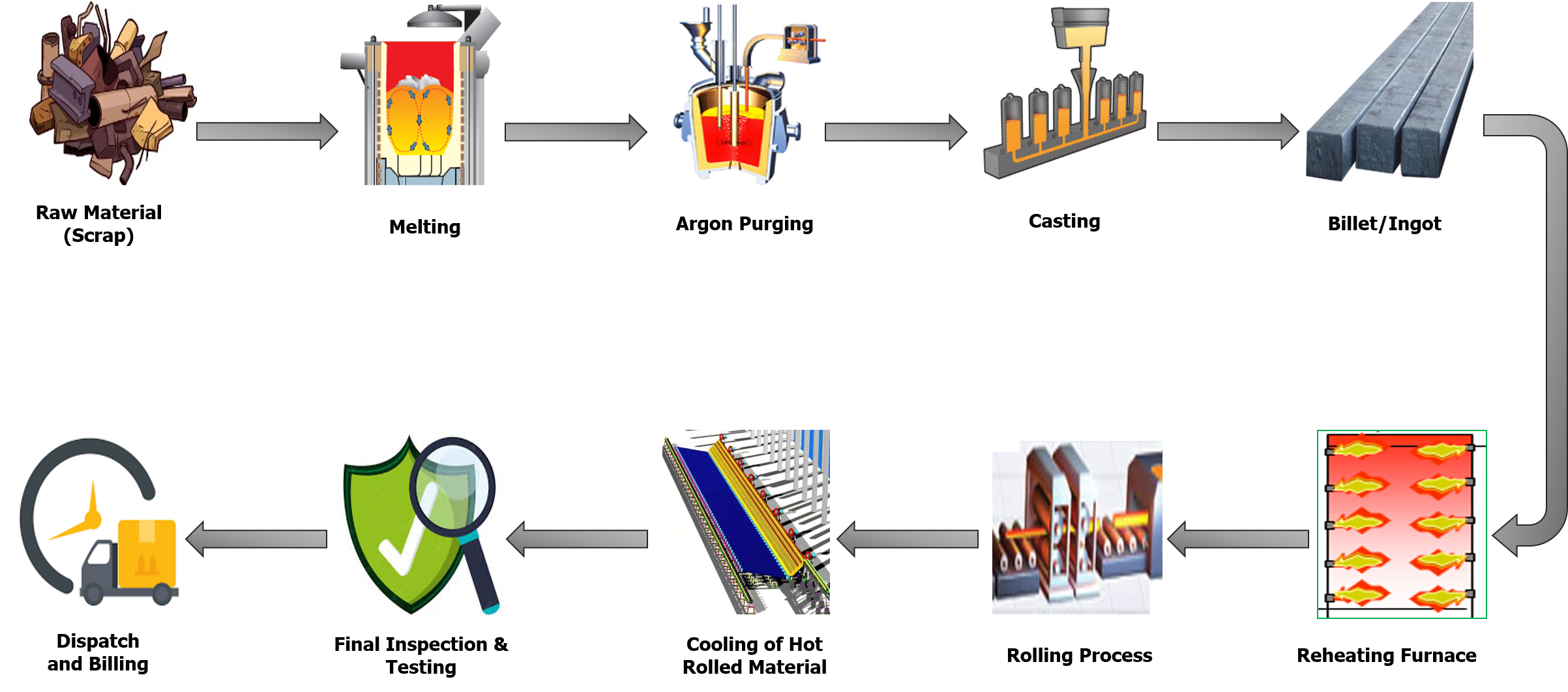

Steel rolling is the process of reducing the cross-section of billets and ingots. The process starts with heating the billets/ingots at extremely high temperature, which is generally approx. 1100 C (above the recrystallization temperature).

Then De-Scaler remove the scale form the surface of heated material. After that material passes through many rolling stands with controlled reduction ratio. Then rolled material hold on cooling bed under controlled and define temperature as per grade. After that material send to cold shear for cutting as per requirement.